creating connections

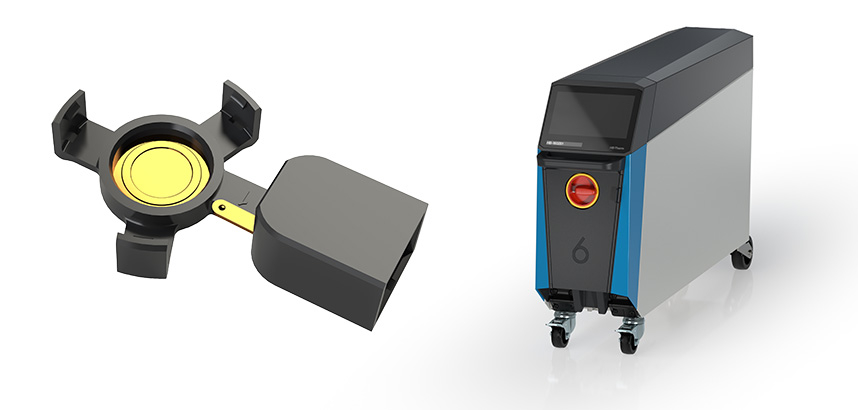

Acoustic transducer for tempering unit

Acoustic transducer for tempering unit

Tempering units are used in injection moulding to adjust the tempering of the moulds to the respective plastics so that the highest possible quality is achieved HB-Therm, the world’s leading manufacturer of tempering units, has brought a new series of units onto the market with the Series 6.

The Thermo-6 tempering units from Vogt AG Verbindungstechnik incorporate a complex assembly and connector housing, which were developed in close cooperation with the customer. The acoustic transducer is an important component of the ultrasonic technology used for flow measurement using the piezo effect. The intelligent device control measures and regulates the temperature up to 230 °C and the flow of the heat transfer medium continuously and with high precision.

The gold-plated stampings of the acoustic transducer have a high conductivity and are protected against corrosion, which contributes to a longer functional service life and fulfils the required quality standard of

the tempering unit manufacturer. The stamping tools and injection moulds were both designed and built in the in-house toolmaking shop. Our production includes the manufacturing of parts from toolmaking to stamping and injection moulding.

Our quality management has technologically first-class testing methods to ensure the quality of series production. Both components produced by us are integral parts of the flow meters in the Thermo-6 tempering units, on which HB-Therm offers a unique lifetime guarantee. When it comes to procurement, the technology leader focuses on high quality and durability.